From “Directions for operating a Collins chain-compensated gasometer”, Second Edition Cat. No. P-469. Warren E. Collins, Inc. May, 1967.

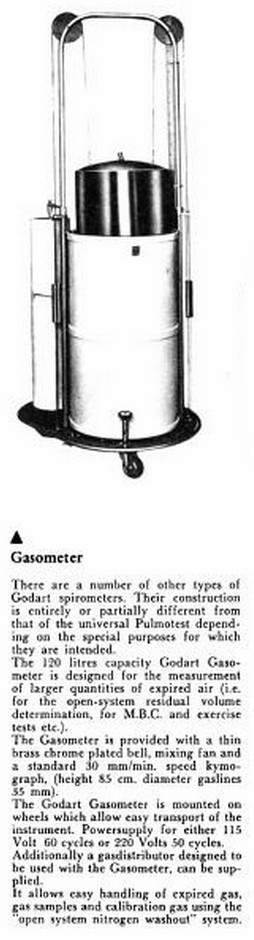

“PRINCIPLE OF CONSTRUCTION

“The Gasometer is made of stainless steel with an outer body and an inner body space about two inches apart to form a water seal for the Spirometer bell fo “float” in. The inner body is also shapes to occlude most of the dead space; and the whole unit is mobile on its own casters.

“CHAIN COMPENSATION

“When the Gasometer is filled with water to the petcock level, and the Spirometer bell is in its lowest position, the bells weighs less than when it is in its highest position, because of the buoyant effect of the water. To automatically compensate for this increasing weight so that the bell will be perfectly counterbalanced throughout its travel, the Collins Gasometer uses a chain to connect the bell to the main counterweight. Thus, as the bell rises, more segments of chain pass over the pulley. As the bell becomes heavier, so does the counterweight in direct proportion, with the result that almost perfect balance is achieved in all positions.

“ATTACHMENTS

“The Gasometer is fitted with the following standard attachments:

“Thermometer – indicates the temperature of the gas within the bell to facilitate various gas volume calculations.

“Auxillary Counterweight – removable so that the Spirometer maybe emptied quickly bu gravity.

“Two-Way Valve – permits addition or subtraction of gas while the patient is breathing. May also be used for sampling.”

Adjustable Height Knob – 120 Liter model: permits telescoping of the chain and pulley downwards. 350 and 600 liter models: pulley supports unscrew. Facilitates transportation and permits moving through low doorways.

“Leveling Screws – assures vertical position of the Spirometer so that the bell will not contact the side of the outer body.

Breathing Branch Assembly – supplies with the 120 liter Gasometer only. It serves as a support for the J-2 Valve or other breathing valves and tubing when the patient is to breathe directly into the Spirometer either from a sitting position or from the bedside.”